Doubel Combustion Chamber

All Incinerators are Doubel Combustion Chamber with One Fuel Burner Each. After Burner Technology for Completely Combustion and Cleaner World.

Read MoreHigh Temperature Incineration

Temperature Range 800 Degree to 1200 Degree in Combustion Chamber. Temperature Thermocouple Monitor and Controller. High Quality Fire Brick and Refactory Cement.

Read MoreGet Lastest News

There are latest incinerator news like technical, public news, business tender for medical waste incinerator,animal incineration, pet cremation

Read MoreNanjing Clover Medical Technology Co.,Ltd.

Email: sales@clover-incinerator.com | Tel: +86-25-8461 0201

Regular model incinerator for market with burning rate from 10kgs to 500kgs per hour and we always proposal customer send us their require details, like waste material, local site fuel and power supply, incinerator operation time, etc, so we can proposal right model or custom made with different structure or dimensions.

Incinerator Model YD-100 is a middle scale incineration machine for many different usage: for a middle hospital sickbed below 500 units, for all small or big size family pets (like Alaskan Malamute Dog), for community Municipal Solid Waste Incineration, etc. The primary combustion chamber volume is 1200Liters (1.2m3) and use diesel oil or natural gas fuel burner original from Italy.

Latest Post

Waste Management Planning

The generator of a waste is responsible for its safe management from cradle-to-grave. Using raw materials efficiently and reducing the amount of waste generated is the most important step in waste management planning. For example, through improved waste management planning, it may be possible to reduce or eliminate the need to burn or incinerate waste altogether. Undertaking a waste audit will help to identify the type and amount of waste being generated, the costs of current management options and examine opportunities for better managing the waste. This information will also enable the generator to implement a waste management regime that is tailored to its own unique needs, location and circumstances.

Even with improved waste reduction measures in place there will be waste generated. Waste by its nature is usually a mixture of different unwanted materials. The segregation and diversion of different types of waste is an effective way to reduce the amount of waste requiring costly handling, storage, treatment and disposal. Segregation also enables the reuse of certain types of waste for a different purpose. Reuse activities may be undertaken either on-site or off-site.

Treatment and disposal is the last step in effective waste management and should be undertaken only after all other practical reduction and reuse options have been examined. A wide variety of treatment and disposal options exist and each must be examined before deciding on a final method, regardless of whether waste is to be treated and disposed of on-site or off-site. If burning and incineration is the method of choice, equipment must be designed and sized accordingly to accommodate the type and quantity of waste being produced. As described in the following section, open burning is capable of safely destroying a limited number of types of waste. While incinerators are capable of safely destroying a wider range of waste, many types of waste must still be diverted. Because of this, on-site segregation remains a critical component of any waste management plan.

Overall, the following principles should be used to guide responsible solid waste management planning:

Know your waste by conducting a waste audit.

Reduce the amount of solid waste produced by implementing strategic purchasing policies that focus on the substitution or reduction of purchased products as well as product design, composition and durability.

Reuse waste where different purposes can be identified.

Segregate and divert mixed waste streams enabling waste to be reused or recycled, thereby reducing the amount of waste to be disposed of.

All practical disposal methods should be examined. Burning and incineration of waste should be considered only where other practical methods do not exist.

If burning and incineration is used, the equipment chosen should be designed and sized to accommodate the waste produced, minimize fire hazard and result in the complete combustion of the waste.

hazardous and biomedical waste

The role of municipal governments is important in the proper local management of solid waste. Under the Nunavut Land Claims

Agreement, municipalities are entitled to control their own municipal disposal sites. Local environmental and safety

standards are determined, in part, by how the land is designated under municipal government development plans (i.e. land use

zoning). Solid waste may be deposited into municipal landfill sites only with the consent of the local government. The local

fire department may also be called upon if a fire or other public safety issue is identified.

Solid waste incinerators are engineered systems that are capable of routinely achieving burn temperatures in excess of 1000oC

and a holding time of at least one second. Properly designed and operated incinerators are able to effectively and safely

destroy a wide range of waste. Only incinerators designed for burning mixed municipal solid waste are discussed in the

guideline. The incineration of

hazardous and biomedical waste and sewage sludge requires specific equipment, operational controls and training that are

beyond the scope of the current document.

There are four basic types of incinerators. They vary based upon the number of burn chambers they have, the amount of air

provided to each chamber and how waste is fed into the primary burn chamber.

Dual-Chamber Starved The primary burn chamber receives less air than is needed to achieve full

Air System combustion. Gases from this incomplete combustion then pass into a second burn chamber where sufficient air

is injected and complete combustion is achieved.

Single Chamber Excess More than a sufficient amount of air (as much as 50% more than the amount

Air System of air needed) is injected into the single burn chamber to achieve complete combustion of the waste.

Continuous Feed An incineration process that is in a continuous burn cycle. A continuous feed

Incinerator incinerator operates without interruption throughout the operating hours of the facility by having waste

continually added to the primary burn chamber.

Batch Feed Incinerator An incineration process that is not in a continuous or mass burning cycle. A batch feed incinerator

is charged with a discrete quantity or single load of waste at the beginning of the burn cycle.

Batch feed dual-chamber controlled air incinerators currently operate at several remote industrial locations in northern

Canada and Alaska. Although they are generally considered to have the highest qualities of all the incinerators and open

burning methods mentioned, they must be designed for the type and quantity of waste to be burned. Too little heat and holding

time will not allow waste to burn properly; too much heat will damage the incinerator.

Figure 5 illustrates the design of a typical batch feed dual-chamber controlled air incinerator. The main features of this

type of incinerator are:

Batch operation allows greater control of temperature and air throughout the burn process. Air turbulence can be reduced in

the primary chamber so fewer particulates are released into the air from the stack.

Although a wide range of wastes can be destroyed, waste may have to be segregated and remixed in order to achieve a

uniform heating value close to the design point of the incinerator.

Externally supplied fuel and electricity are needed for the burners and forced air ventilation. A properly operating dual-

chamber controlled air system will reduce problems with animal attraction as the production of bottom and fly ash and smoke

is minimized.

Section 2.3.2 is intended to provide the reader with a brief introduction to incinerators. It is not intended to provide

information suitable for the design, selection or operation of an incineration system. Any person considering the purchase of

an incineration system should first consult the system’s manufacturer or other qualified persons with expertise in the

incineration of solid waste.

Incinerator Maximizing Combustion Efficiency

More smoke and other pollutants are released into the air during the ‘start-up’ and ‘cool down’ phases of the burn cycle

than during the ‘full burn phase’ when high temperatures are maintained. Low temperature smoldering fires should be

avoided. Burn only dry feedstock and periodically add additional waste to the fire in order to maintain high burn

temperatures until all waste has been destroyed. If waste is to be open burned on the ground, the use of deep or steep-walled

‘pits’ should be avoided as this will prevent the necessary turbulent mixing of oxygen with the burnable gases.

Desired operating temperature should be achieved as quickly as possible when operating any burning or incineration device. A

rapid ‘start-up’ can be achieved by first loosely loading dry paper, paperboard packing and untreated wood into the bottom

of the device. Dry, loosely loaded material will ignite more quickly and burn more evenly than a wet, tightly packed load.

Wet waste should only be added after the fire is actively burning. Overfilling the burn chamber will prevent the turbulent

mixing of burnable gases and oxygen, and should be avoided.

Modern batch feed incinerators are designed with primary and auxiliary burners to achieve and maintain the necessary high

burn temperatures. Additional waste should only be added to these incinerators once the ‘cool down’ phase has been

completed and it is safe to do so.

Air Emissions Environmental Standards CA

Air emission standards establish limits on the amount of contaminants that can be released into the atmosphere. These standards are expressed as a concentration in the exhaust gases leaving the stack and are capable of being achieved using generally available incineration technology and waste diversion practices. The following emission standards1 apply to existing, new or expanding solid waste incinerators operating in Nunavut and have been adopted from the Canadian Council of Ministers of the Environment (CCME) Canada-Wide Standards for Dioxins and Furans and Mercury Emissions, respectively. Similar standards for the open burning of solid waste have not been established.

Table 1. Air Emission Standards for Solid Waste Incinerators

Parameter Numeric Standard Explanation

Dioxins and Furans

80 pg I-TEQ/cubic metre

Unit of measure is picograms of International Toxicity

Equivalents per cubic metre of air

Mercury

20 µg/Rcubic metre

Unit of measure is micrograms per Reference cubic metre (the volume of gas adjusted to 25oC and 101.3 kilopascals)

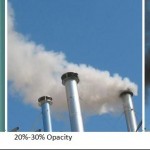

Opacity is the degree to which the exhaust gases reduce the transmission of light and obscure the view of any object in the background. It is expressed as a percentage representing the extent to which an object viewed through the gases is obscured. Although not an emission standard, opacity provides an indication of the general performance of the incinerator during normal operation2. Opacity in the incinerator stack should not exceed 5%. While it is not anticipated that opacity levels would exceed 1% to 2% under normal operation, values greater than 5% indicate the incinerator is not performing properly and additional performance evaluation and adjustment is required.

Figure 6 – Examples of Smoke Opacity Ratings

The opacity ratings are estimates and are provided for illustrative purposes only

Centre and right photos courtesy of GNWT Department of Environment and Natural Resources

Wastes That Can be Burned or Incinerated

Complete combustion converts waste into inert bottom ash with minimal creation of smoke, fly ash and hazardous

gases. Several factors influence this process including the heating value, wetness and chemical composition of the

waste itself, operating conditions in the burn chamber (i.e. temperature, holding time and turbulence) and

operator skill.

The method used is important in determining what can safely be burned. Certain wastes can only be incinerated

using equipment that has been specifically designed and equipped with sufficient air pollution controls and that

achieve specific air emission standards. For example, waste containing chlorinated compounds (i.e. chlorinated

solvents and plastics, PVC piping, wood treated with pentachlorophenol or PCB-amended paint, marine driftwood)

must be separated from other waste as their burning will result in the de novo creation and emission of various

dioxin and furan compounds. Waste containing mercury (i.e. batteries, thermostats and fluorescent light bulbs) and

other heavy metals (i.e. lead acid batteries, wood treated with lead paint) should not be burned as the mercury

and heavy metals will not be destroyed. Other waste that should not be burned unless using specially designed

incinerators include used lubricating oil, hydrocarbon contaminated soil, biomedical waste, sewage sludge or any

other waste specifically prohibited by the Department of Environment.

Table 2 provides a listing of common wastes that can be burned and those that require special consideration and

treatment. Note that open burning and incineration are identified as separate columns in the table and that

different restrictions apply depending upon which method is used. In general, more restrictions apply to the

various methods of open burning because of the incomplete combustion achieved. Fewer restrictions apply to

incineration because of the operator’s ability to control the combustion process.

Non-combustible materials such as metal and glass do not burn and will rob heat away from waste that can be

destroyed by burning. Combustible waste should always be separated from non-combustible waste before being loaded

into the burn chamber.