WHO-Supported Medical Waste Incineration Projects: Improving Public Health and Environmental Safety Worldwide

Effective and safe treatment of healthcare waste is a critical component of global health systems. Over the past two decades, the World Health Organization (WHO) has supported numerous projects focused on medical waste incineration, aiming to protect healthcare workers, patients, and communities from infectious and hazardous waste.

These projects combine technical guidance, procurement of appropriate technologies, and capacity building to ensure sustainable solutions in both low- and middle-income countries.

Project Examples and Geographic Focus

1. African Health Facility Waste Management Program (2008C2015)

-

Supported by WHO, the World Bank, and national ministries of health.

-

Countries included: Ghana, Nigeria, Kenya, Tanzania, Ethiopia, and Zambia.

-

Installed dual-chamber diesel-fired incinerators (50C100 kg/hour) in over 100 district hospitals.

-

Technical specification:

-

Primary combustion chamber ≥ 800°C.

-

Secondary chamber ≥ 850°C with residence time ≥ 2 seconds.

-

Chimney height ≥ 8C12 meters.

-

-

Achievements: Reduction in open burning, significant improvement in operator safety, and compliance with national environmental standards.

2. WHO / UNICEF Immunization Waste Management Initiative

-

Focused on safe disposal of sharps and used syringes from vaccination campaigns.

-

Regions: West Africa, South-East Asia, and parts of Central Asia.

-

Procured small-capacity incinerators (10C30 kg/hour) for rural health centers and mobile vaccination teams.

-

Supported deployment of portable incinerators and training for local staff.

-

Goals achieved: Elimination of needle-stick injuries, reduction of environmental contamination in rural and peri-urban areas.

3. WHO / Gavi Medical Waste Support for Measles and Polio Campaigns

-

Provided technical guidelines and funded installation of incinerators at temporary field sites and central vaccine storage centers.

-

Technical highlights:

-

Dual-chamber design with temperature monitoring.

-

Automatic burners with diesel or LPG fuel options.

-

Mobile or skid-mounted versions for remote locations.

-

-

Outcomes: Safe disposal of millions of syringes and vaccine vials; improved biosecurity during mass immunization drives.

4. Strengthening Hospital Waste Management in Post-Conflict Countries

-

Examples: Afghanistan, South Sudan, Somalia, Sierra Leone, and Liberia.

-

WHO collaborated with NGOs (e.g., MSF) and UN agencies (e.g., UNDP, UNICEF) to supply containerized incinerators for district hospitals and field hospitals.

-

Typical models: 30C75 kg/hour, dual-chamber, PLC-controlled.

-

Achievements: Enabled hospitals to operate safely during crises; reduced risk of hospital-acquired infections and community exposure to infectious waste.

Technical Specifications Common Across WHO Projects

Across these projects, WHO-supported procurement generally specifies:

-

Dual combustion chambers: primary ≥ 800°C; secondary ≥ 850°C.

-

Automatic temperature control and data logging.

-

Diesel, LPG, or hybrid fuel systems adapted to local availability.

-

Chimney height and design to ensure effective dispersion of residual emissions.

-

In some contexts: wet scrubbers or filters to further reduce particulate emissions.

Goals and Public Health Impact

WHO’s incineration support projects typically aim to:

-

Safely destroy infectious waste at the point of generation.

-

Protect healthcare workers and waste handlers from injury and infection.

-

Reduce reliance on uncontrolled burning or shallow burial.

-

Align national waste management practices with Basel Convention and Stockholm Convention guidelines.

-

Build local capacity through operator training and maintenance planning.

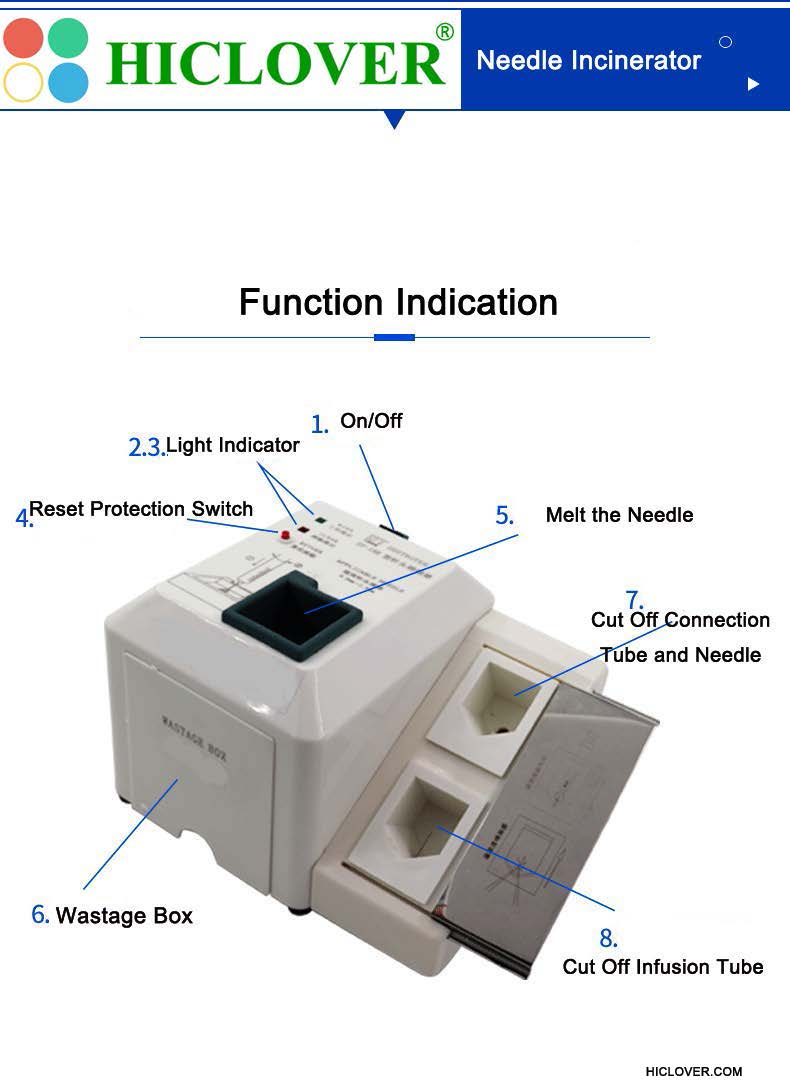

The Role of Manufacturers like HICLOVER

Manufacturers supplying WHO-supported or similar donor-funded projects often provide:

-

Containerized, mobile, or fixed incinerators matched to the capacity needs of hospitals.

-

PLC-based control systems and automatic burners from recognized international brands.

-

Installation support, spare parts, and operator training to ensure long-term sustainability.

Models such as the HICLOVER TS30, TS50, TS100, and TS150 PLC series match the typical technical and operational requirements of WHO projects:

-

Dual-chamber design.

-

High combustion temperature.

-

Compact footprint and low fuel consumption.

-

Flexible installation in urban or remote areas.

WHO-supported medical waste incineration projects have transformed waste treatment practices in dozens of countries, reducing infection risks and environmental impact.

Through practical, technically sound equipment and ongoing capacity building, these projects help hospitals and health systems safely manage growing volumes of hazardous waste.

For technical details, customized proposals, or references from similar international projects, visit:

www.hiclover.com

sales@hiclover.com

HICLOVER C providing high-temperature, dual-chamber incinerators trusted by public health and humanitarian projects worldwide.

- smart